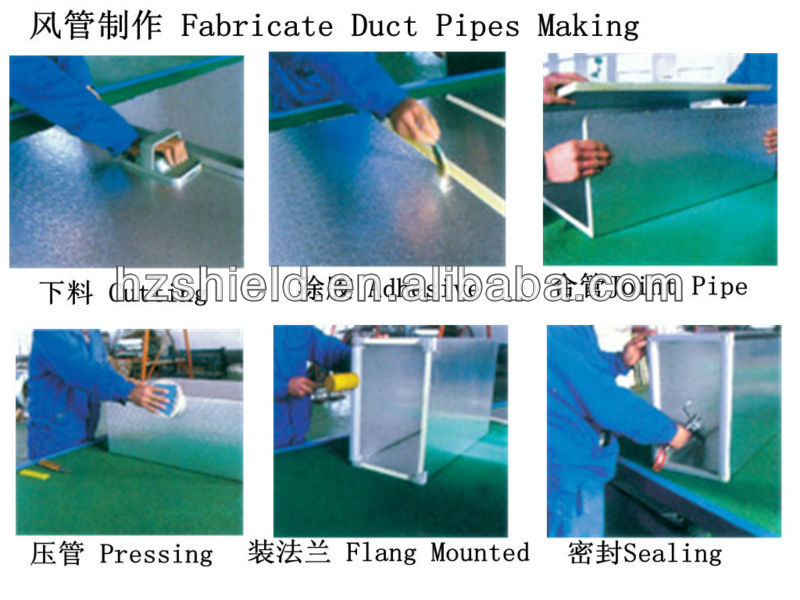

Our air duct foam board is mainly made with extruded polystyrene (XPS) and phenolic foam core with two sides aluminium foil covered. It is new style of HVAC Ductwork at present. It is an excellent alternative to traditional galvanized Iron (sheet metal) duct work. It is ideal for application where space or weight is restricted. Compared to heavy metal ducting which requires a second step to its installation process of both vapour seal and thermal insulation, our xps and phenolic foam air duct offers a high performance, lightweight and robust ductwork system which requires only a single fix installation process. It can provide a high speed installation and save space and cost.

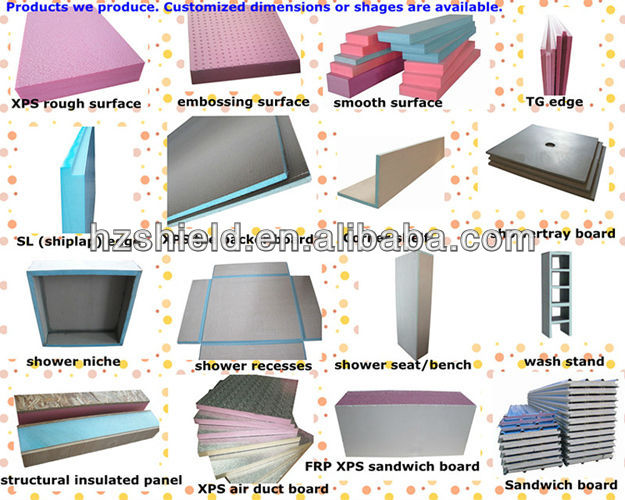

XPS Air Duct Foam Board

XPS air duct foam board is made with extruded polystyrene (XPS) foam board laminated two surfaces aluminium foil. It is widely used in varieties of Ventilation System. Core materials XPS board is inside closed-cell foam structure, with high compressive strength, light weight etc..

Advantages:

1.High compressive strength

2.Waterproof, moisture proof and air proof

3.Low thermal conductivity ensures excellent insulation property

4.Light weight makes convenient for transportation and handling duct work

5.Easy installation, save cost, save space

6.Long service Life: anti-corrosion, no toxic

7.Environment protection, no pollution, renewable and recyclable

Standard Size

Length (mm) | Width (mm) | Thickness (mm) |

2950 | 1200 | 20 |

35 |

40 |

3950 | 1200 | 20 |

35 |

40 |

Note: 1. Can make one side foil covered or double side foil covered.

2. Special dimensions can be customized.

Technical Data

XPS Density | Kg/M3 | 36-40 |

Thermal Conductivity | W/(M.K) | 0.028-0.036 |

Compressive Strength | Kpa | 150-300 |

Bending Strength | Mpa | 0.85-1.26 |

Dimensional Stability | % | ≤1.0 |

Water Absorption | %-vol | ≤ 1.0 |

Combustion Property | Class | B3, B2, B1 |